Carbide Saw Blade

Email with us today to get the best deals and fastest deliveries on related carbide tools!

Category:

24-hour hot line:

E-mail:

Product Details

Product parameters

|

Name (Saw blade) |

Material (Solid carbide) |

Processing hardness (Below HRC55) |

|

Workpiece: Stainless steel, steel parts, iron, cast iron, aluminum, aluminum alloy, titanium alloy, etc. |

||

|

Features: It is mainly used for slot milling and milling of ordinary steel, iron, copper, aluminum, especially stainless steel, hardened steel, titanium alloy, printed circuit board and other difficult-to-machine materials. It is 6-7 times longer than the high-speed steel (white steel) saw blade milling cutter, with precise size and good finish, high cost performance and high efficiency. |

||

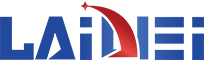

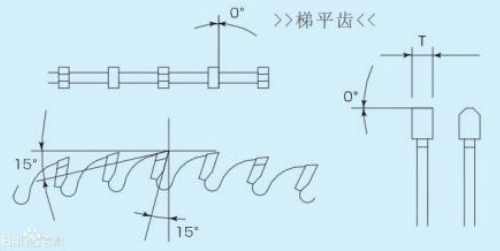

Example of Tooth Profile

| Left and right tooth shape

(alternate teeth) |

|

|

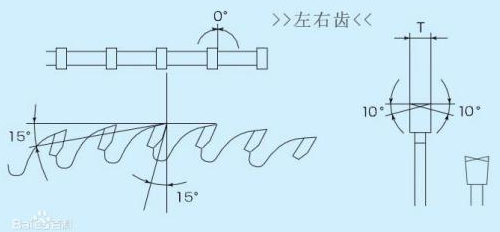

Ladder flat teeth |

| Dovetail teeth

(anti-rebound dovetail teeth) |

|

|

Flat teeth, inverted ladder teeth |

|

|

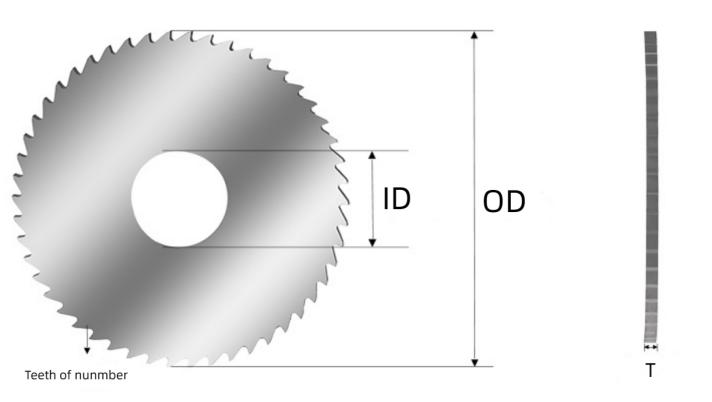

Select the sizes that you want!

|

OD |

Thickness |

ID |

Number of teeth | |||

|

Basic size |

Tolerance |

Basic size |

Tolerance |

Basic size |

Tolerance |

|

|

12 |

±0.090 |

0.1-10 |

±0.012 |

5/6 |

+0.0120 |

12/18/24/30/36/40 |

|

16 |

±0.090 |

0.1-10 |

±0.012 |

5/6 |

+0.0120 |

12/18/24/30/36/40/50 |

|

20 |

±0.105 |

0.1-10 |

±0.012 |

6/8 |

+0.0120 |

18/24/30/36/40/50/60/72/80 |

|

25 |

±0.105 |

0.1-10 |

±0.012 |

6/8 |

+0.0150 |

18/24/30/36/40/50/60/72/80 |

|

32 |

±0.105 |

0.1-10 |

±0.012 |

8/10/12.7/13 |

+0.0150~ +0.0180 |

18/24/30/36/40/50/60/72/80 |

|

40 |

±0.105 |

0.15-10 |

±0.012 |

8/10/12.7/13 |

+0.0150~ +0.0180 |

30/36/40/50/60/72/80/90 |

|

45 |

±0.105 |

0.2-10 |

±0.012 |

12.7/13/16 |

+0.0180 |

36/40/50/60/72/80/90/100 |

|

50 |

±0.105 |

0.2-10 |

±0.012 |

12.7/13/16 |

+0.0180 |

40/50/60/72/80/90/100/120 |

|

60 |

±0.105 |

0.2-10 |

±0.012 |

12.7/13/16/22/25.4 |

+0.0180 |

40/50/60/72/80/90/100/120 |

|

63 |

±0.105 |

0.3-10 |

±0.012 |

12.7/13/16/22/25.4 |

+0.0180 |

40/50/60/72/80/90/100/120 |

|

70 |

±0.105 |

0.4-10 |

±0.012 |

12.7/16/22/25.4/27 |

+0.0210 |

40/50/60/72/80/90/100/120 |

|

75 |

±0.105 |

0.4-10 |

±0.012 |

16/22/25.4/27 |

+0.0210 |

40/50/60/72/80/90/100/120 |

|

80 |

±0.105 |

0.5-10 |

±0.012 |

22/25.4/27 |

+0.0210 |

50/60/72/80/90/100/120/150 |

|

100 |

±0.105 |

0.8-10 |

±0.012 |

22/25.4/27 |

+0.0210 |

50/60/72/80/90/100/120/150 |

|

125 |

±0.105 |

1.2-10 |

±0.012 |

22/25.4/27/32 |

+0.0210~ +0.0250 |

50/60/72/80/90/100/120/150 |

|

150 |

±0.105 |

1.4-10 |

±0.012 |

25.4/27/32 |

+0.0210~ +0.0250 |

50/60/72/80/90/100/120/150 |

|

180 |

±0.105 |

1.6-10 |

±0.012 |

25.4/27/32 |

+0.0210~ +0.0250 |

50/60/72/80/90/100/120/150 |

|

200 |

±0.105 |

2.0-10 |

±0.012 |

25.4/27/32/40 |

+0.0210~ +0.0250 |

50/60/72/80/90/100/120/150/180 |

|

1. Special requirements for some small outer diameters: the thinnest thickness can be 0.10. 2. If there is a special requirement for high precision, the thickness tolerance can also be ±0.003. 3. Special outer diameters, thicknesses,inner diameters, and number of teeth can be customized. |

||||||

Previous Page

Next Page

Previous Page

Next Page

Product Consultation